Deploying innovation, technology and sustainability at all levels of manufacturing

Research & Development

Producing world-class products with state-of-the-art technology

We boast a dedicated team of experts in our R&D department to not just ensure that our customers get access to the best products and services, but also aid in achieving our sustainability goals. Our R&D department covers three key aspects that make us achieve our commitment towards producing top-of-the-line products and being environmentally conscious across all our inter-functional departments.

Product and Quality Development

Ever since our inception, TNPL has been devoted towards manufacturing products that are only of the finest quality. Integrating ultra-modern technology with optimized operations, we are now one of the world leaders in the pulp and paper industry. The following are a standing testament of our commitment towards our product quality:

- Integration with revolutionary technology to ensure low steam consumptions and high and uniform pulp quality.

- With constant upgradation and innovation, our production quantity has increased from 90,000 TPA – 6,00,000 TPA to this date.

- Installation of a 300 TPD deinked pulp line of 3 Loop 2 disperger configuration with two-stage bleaching to produce PWP grade deinked pulp

- Ensurance of suitability and performance of chemicals by conducting functionality tests.

- Optimization of pulp furnish, coating formulation and chemical additives that aids in massive cost cutting.

- Nano blinder trials conducted to reduce the cost of blinder without compromising on the functionality.

Promoting Sustainability

- We are known for our environmental consciousness and eco-friendliness in the country with the least water consumption.

- The wastewater generated in the mill is treated with our advanced water treatment plant and repurposed as process water and is also utilized for irrigation purposes.

- Utilizes 1 million tonnes of bagasse, a renewable residue from sugarcane, avoiding about 30,000 acres of forest land from commercial exploitation.

- Reduction of energy consumption in our ETP by 2000 units per day.

- Poly Lactic Acid extrusion coating trials have been successfully conducted to replace PE coating, along with Online Barrier Coating trials and both products have been certified for Compostability by CIPET, Kochi.

- Sustainable Forest Management: TNPL boasts FSC-FM and FSC-CoC certified captive plantation and farm forestry for pulpwood, which serves as a major raw material for paper and packaging boards.

Sustainable Manufacturing

We are firm believers that one operations’ waste could be another’s fuel and we are developed on the concept of “Waste to Wealth”. We ensure that most of the waste that we generate is reused, recycled and repurposed to the maximum extent possible at all levels of our production.

Employing waste to wealth’ manufacturing across inter-functional operations

- For starters, the major raw material used for our paper production is bagasse, which is a sugarcane residue.

- Recycling of waste paper – waste paper is also utilized as one of the raw materials for pulp production.

- The solid waste generated from the paper mill’s power plant such as lime sludge, deinked pulp sludge and dip sludge are repurposed to produce industry-grade cement.

- Deployment of a robust research facility for bioenergy and biotechnology to produce artificial plant cells and clones through tissue culture, developed as seedlings and further reused as a raw material in the paper production.

- Production of biogas from the bagasse wash water, which is further used to replace fossil fuels for reduced emissions.

- The wood dust and pith generated from bagasse are repurposed into agro fuels that is in turn used in multitudes of operations.

Infrastructure

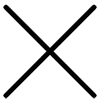

Adopting avant-garde equipment to ensure Low-waste Manufacturing

Right from the inception of our first plant in Kagithapuram, through the years, we have always strived to deploy state-of-the-art equipment that makes us stay environmentally conscious and eco-friendly across all our operations.

Paper

Commenced in Kagithapuram, Karur District in 1984, through the years, our paper mill has evolved with various equipment installed to make our process more efficient, seamless, and environment-friendly. Some of the revolutionary equipment that our paper mill possesses are

- ECF bleaching, oxygen delignification, and integrated chlorine dioxide production to remove elemental chlorine and prevent the formation of dioxins and carcinogens.

- Adoption of Vamlet Auto Paper Lab from Finland – one of the most modern fully automated paper-testing instruments in the world.

- Gas Chromatograph – the only Paper Mill in India equipped with a sophisticated chromatograph for evaluation of gaseous components that is applicable to Clean Development Mechanism and Carbon Footprint.

- Horizontal L&W Tensile Tester from Germany – An advanced instrument that helps test the physical properties of paper and board, making sure that every sheet we make has only the finest quality.

- Leica DRMB Stereo Microscope, Germany – One of the most powerful, ergonomically designed microscopes which is reliable for multitudes of applications including inspection, observation, documentation or dissection of a plant sample and has proven to deliver impactful results.

- Incinerator for Non-Condensable Gases

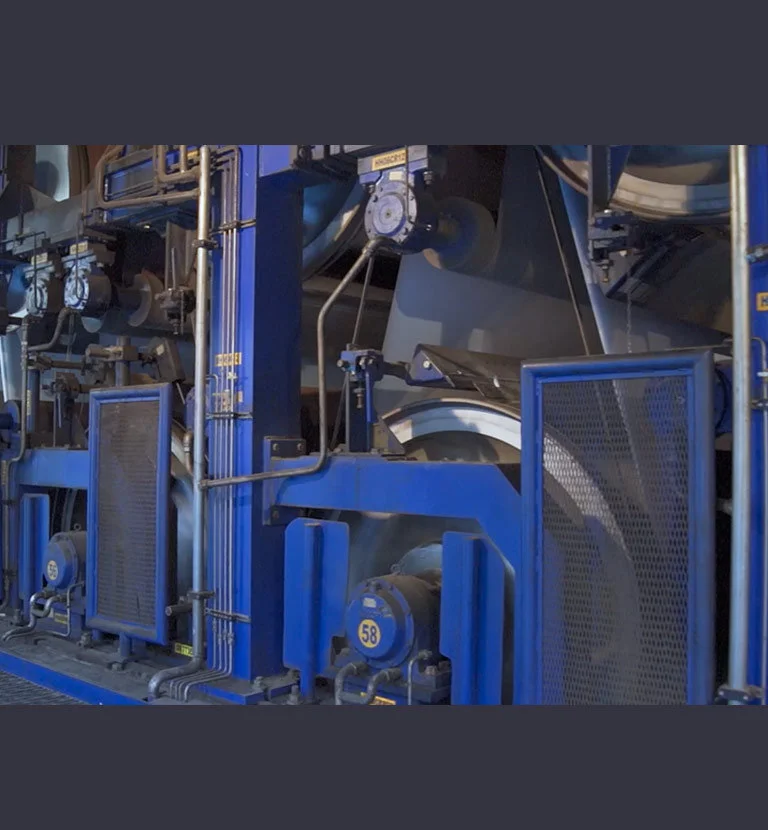

Packaging Board

Set up in 2016, with a capacity of 200,000 MT per annum, TNPL’s Paperboard Unit boasts ultra-modern technology in place that aids in optimized operational efficiency, adopting low waste across all levels of manufacturing. Some of the world-class equipment that our Unit II boasts are

- AUTOLAB, Metso, Switzerland – A state-of-the-art quality control laboratory to test the paperboard properties across the deckle, providing the most precise results without any manual intervention.

- Optitopo from Lorentzen and Wettre, Sweden – for optical topography measurement of the paperboard surface. This instrument is used to identify the uniformity of the surface and to gauge the surface undulations in micron levels, which in turn impacts the printability of the board.IGT Amsterdam 2 for lab scale is used for the evaluation of print quality of the final board. This includes dry pick, wet pick, print blister and print uniformity tests to get an all-round analysis of the paperboard’s quality.

- A Laboratory Calander is designed in-house to assess the paperboard surface at various conditions of nip load and temperature.

- Multi-layer Coated Paperboard Machine with a 30 MW captive cogeneration power plant

- Top-of-the-line Automatic Storage and Retrieval System (ASRS) with a capacity to store 30,000 MT reels and 6,000 MT sheets.

- High efficiency boilers with atmospheric fluidised combustion technology

- Facilitations to recover white water for aggravated reuse

- Variable Frequency Drives for optimized consumption of raw materials.

Cement

Being the industry leader in adopting sustainable technologies and innovation, TNPL cement is manufactured with solid waste such as fly-ash and lime sludge that is generated from our paper mill. In fact, our Unit II in Mondipatti, Trichy was constructed entirely using the cement that we manufactured, making us achieve circular economy at all levels of production.

- Amtek Spectro iQ II XRF Analyzer – A sophisticated X-Ray Fluorescence Spectrometer with high resolution, repeatability and reproducibility to test the chemical composition of cement, incoming raw materials and in-process materials with utmost accuracy levels.

- Auto Blaine Apparatus to find out the fineness of cement

- Compression Strength Testing Machine for testing of 3 day, 7 day and 28 day compressive strength of cement mortar cubes.

- Humidity Chambers for maintaining three different temperatures and relative humidity for curing Cement Mortar Cubes, Fly-Ash cubes and Cement Drying Shrinkage bars

Technology Absorption

Implementing revolutionary technology from the world across all processes

We have always been the torch-bearers of innovation, and thus all our operations are optimized with the adoption of futuristic and relevant technologies from all over the world. We always strive for excellence in everything we do and pool in industry-best practices from across the globe and ensure that we set a benchmark of our own for products of top-notch quality.

With our vision set to become the world market leader to not just manufacture the most eco-friendly products, but also implement sustainability across all our operations, we are constantly upgrading ourselves with the latest and forward-looking technology available in the market.